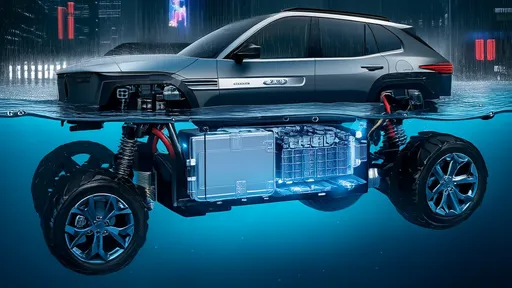

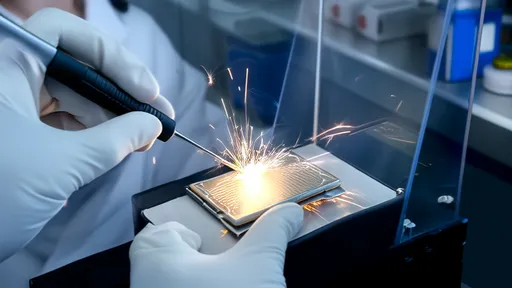

The battery nail penetration test has become a cornerstone of safety evaluations in the lithium-ion battery industry. Designed to simulate internal short circuits caused by physical damage, this controversial test pushes batteries to their thermal limits while revealing critical differences between standardized procedures and real-world failure scenarios. As electric vehicles and energy storage systems demand increasingly robust safety assurances, the gap between laboratory conditions and unpredictable field environments raises pressing questions about how we define true battery safety.

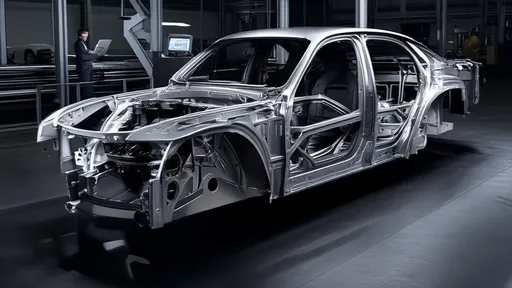

At its core, the nail test involves driving a conductive metal rod (typically 3-8mm in diameter) through a fully charged battery cell at controlled speeds while monitoring temperature, voltage, and thermal runaway propagation. Industry standards like GB/T 31485 in China and UL 2580 in North America prescribe specific parameters, but these idealized conditions often fail to account for the chaotic variables present in actual accidents. The controlled laboratory environment—with its thermal chambers and precisely positioned nails—creates a false sense of security that doesn't translate to crumpled vehicle frames puncturing battery packs at odd angles during highway collisions.

Manufacturers walk a tightrope between regulatory compliance and genuine safety engineering. Some cells pass certification tests by incorporating thin metal layers that melt upon penetration, temporarily isolating electrodes before catastrophic thermal runaway. While effective under test conditions, such designs may provide limited protection against multiple penetration points or prolonged short circuits occurring in real accidents. The automotive industry has witnessed cases where cells passing nail tests still experienced cascading failures when damaged in uncontrolled environments.

Thermal propagation presents another critical divergence between test scenarios and reality. Standard tests often evaluate single cells in isolation, whereas pack-level failures involve complex interactions between hundreds of cells. The spacing between cells, coolant flow patterns, and structural integrity of modules create variables no single-cell test can accurately replicate. Recent battery fires in energy storage systems have demonstrated how thermal runaway in one cell can bypass protective systems designed for standardized failure modes.

Material science innovations are quietly reshaping the nail test's relevance. Phase-change materials that absorb tremendous heat, ceramic-coated separators with higher melt points, and self-healing electrolytes are changing failure dynamics. These advancements render traditional pass/fail criteria increasingly obsolete—a cell that appears dangerous during nail penetration might contain the failure through novel chemistry rather than prevent it entirely. Regulatory bodies now face the challenge of updating test protocols to account for these technological leaps.

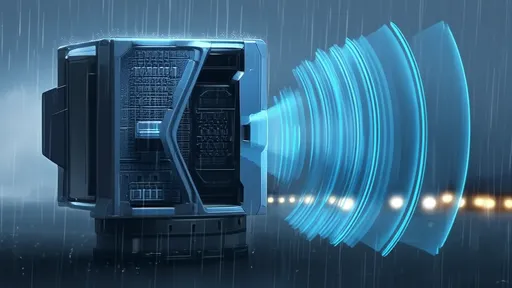

The velocity and angle of penetration prove far more consequential than most standards acknowledge. Research from the National Renewable Energy Laboratory shows that nails driven at automotive crash speeds (20-50mm/ms) create fundamentally different short circuit behaviors compared to the 1-10mm/s speeds used in certification tests. The rapid mechanical deformation alters internal architecture before protective mechanisms can activate, often resulting in more violent failures. This explains why some battery packs certified as safe have still suffered catastrophic thermal events in high-speed collisions.

Real-world damage rarely resembles the clean punctures of laboratory tests. Crumple zones create complex deformation patterns that simultaneously damage multiple cell locations, while road debris may introduce conductive contaminants that exacerbate short circuits. These multidimensional failure modes expose a fundamental limitation of single-vector penetration tests. Some European automakers have begun supplementing standard nail tests with multi-axis intrusion simulations that better replicate crash dynamics.

Battery safety engineering is evolving beyond the binary pass/fail mentality of traditional nail testing. Progressive manufacturers now employ computational models that simulate thousands of failure scenarios, combining mechanical damage with electrical and thermal analyses. This probabilistic approach better accounts for real-world variables while highlighting how standardized tests represent merely one point in a vast spectrum of potential failure modes. As battery chemistries diversify and applications multiply, the industry must develop safety frameworks that transcend outdated yes/no validation methods.

The psychological impact of nail testing cannot be overlooked. While serving as a valuable comparative tool, its prominence in marketing materials creates unrealistic consumer expectations about absolute safety. No standardized test can possibly replicate the infinite variability of real-world conditions—a reality the industry must communicate more transparently. Moving forward, safety protocols will likely incorporate performance bands rather than binary outcomes, acknowledging that risk mitigation exists on a continuum rather than as an absolute achievement.

Emerging alternatives to nail testing may eventually redefine how we evaluate battery safety. X-ray computed tomography can non-destructively analyze internal damage progression, while advanced sensors provide real-time mapping of thermal and electrical anomalies during controlled failures. These techniques offer more nuanced safety data than the crude metrics of traditional penetration tests. However, the nail test's simplicity ensures its continued role as a baseline benchmark, even as more sophisticated evaluation methods gain traction.

As battery technology outpaces safety standards, a fundamental philosophical question emerges: Are we testing for regulatory compliance or genuine survivability? The answer will shape the next generation of energy storage systems, determining whether safety engineering remains bound by standardized checklists or evolves to address the beautiful chaos of the physical world. What remains certain is that the humble nail test, for all its limitations, has spurred critical conversations about the complex relationship between controlled validation and unpredictable reality.

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025