The automotive industry has witnessed a significant shift in design preferences over the past decade, with panoramic sunroofs—commonly referred to as "panoramic sunroofs" or "panoramic roofs"—becoming a highly sought-after feature among consumers. These expansive glass panels, which often stretch from the front windshield to the rear of the vehicle, provide an open, airy cabin experience while maintaining structural integrity. However, the integration of such large glass surfaces into a vehicle's roof raises critical questions about safety, particularly concerning roof crush resistance. As regulatory standards tighten and consumer expectations rise, automakers are investing heavily in advanced materials and structural reinforcement techniques to ensure that panoramic sunroofs meet stringent safety requirements without compromising aesthetics or functionality.

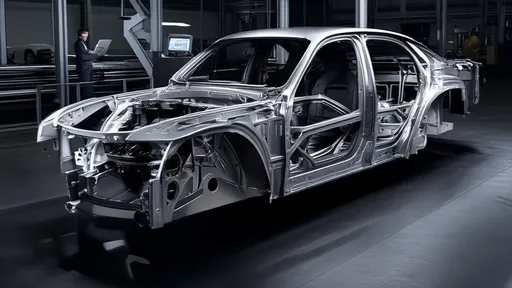

Roof strength has long been a focal point in vehicle safety, with organizations like the National Highway Traffic Safety Administration (NHTSA) and the Insurance Institute for Highway Safety (IIHS) establishing rigorous testing protocols. Traditional metal roofs are inherently robust, but the transition to glass-dominated designs necessitates innovative engineering solutions. Unlike conventional sunroofs, which occupy a relatively small portion of the roof, panoramic sunroofs require extensive reinforcement to distribute impact forces effectively. Engineers achieve this through a combination of high-strength steel or aluminum framing, tempered or laminated glass with enhanced fracture resistance, and strategic placement of load-bearing pillars. The goal is to ensure that the roof can withstand multiple times the vehicle's weight in the event of a rollover, a key metric in safety evaluations.

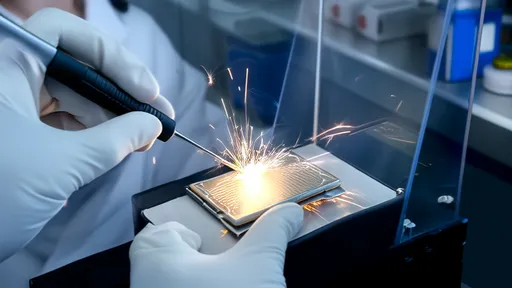

One of the primary challenges in designing panoramic sunroofs is balancing transparency with structural rigidity. Glass, by nature, lacks the ductility of metal, making it more susceptible to catastrophic failure under extreme stress. To mitigate this risk, automakers employ laminated glass, which consists of multiple layers bonded by a polyvinyl butyral (PVB) interlayer. This construction not only prevents shattering but also helps maintain the roof's shape during deformation, reducing the risk of occupant ejection. Additionally, the surrounding framework is often reinforced with ultra-high-strength steels or carbon fiber composites, creating a "safety cage" that channels crash forces away from the glass. These materials are meticulously shaped and welded to form a continuous load path, ensuring that energy from an impact is dissipated throughout the vehicle's structure rather than concentrated on the sunroof.

Beyond material selection, the geometry of the panoramic sunroof plays a pivotal role in its crashworthiness. Engineers use finite element analysis (FEA) to simulate various crash scenarios, optimizing the curvature and thickness of the glass as well as the positioning of support beams. For instance, some designs incorporate subtle arches or reinforced edges to enhance stiffness, while others use cross-car beams hidden within the headliner to provide additional support. The integration of these elements must be seamless to preserve the sunroof's sleek appearance, which is a major selling point for consumers. Furthermore, advanced bonding techniques, such as structural adhesives combined with mechanical fasteners, ensure that the glass remains securely anchored to the frame even under severe loads.

Real-world validation is a crucial step in the development process. Automakers subject prototypes to dynamic rollover tests, static roof crush tests, and pendulum impacts to evaluate performance under extreme conditions. These tests often exceed regulatory requirements to account for unpredictable scenarios, such as multi-vehicle collisions or impacts with uneven surfaces. Data from sensors embedded in test dummies and high-speed cameras provide insights into how the roof deforms and whether occupants are adequately protected. Iterative refinements based on these findings help engineers strike the optimal balance between weight, strength, and design elegance. As a result, modern panoramic sunroofs can now achieve safety ratings comparable to—or even surpassing—those of traditional metal roofs.

Looking ahead, the evolution of panoramic sunroof technology shows no signs of slowing. Emerging trends include the use of electrochromic glass, which can adjust transparency at the touch of a button, and embedded solar cells that harness sunlight to power auxiliary systems. However, these innovations must not come at the expense of safety. Future designs will likely incorporate even stronger glass composites, active reinforcement systems that stiffen the roof in anticipation of a crash, and advanced sensors that monitor structural integrity in real time. As automakers continue to push the boundaries of what's possible, one thing remains clear: the marriage of panoramic views and uncompromising safety is here to stay.

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025