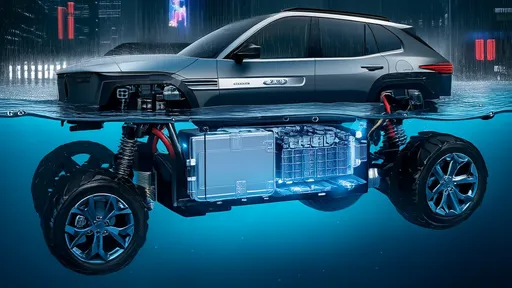

The growing adoption of electric vehicles (EVs) has brought new engineering challenges to the forefront, particularly when it comes to water exposure. Unlike traditional internal combustion engine vehicles, EVs rely heavily on high-voltage systems that are far more sensitive to moisture ingress. The risks associated with water intrusion—ranging from electrical shorts to catastrophic battery failures—demand rigorous design considerations, especially as automakers push for higher wading depths to match or exceed conventional off-road capabilities.

Water and electricity have never been a safe combination, and this axiom becomes even more critical in the context of EVs. High-voltage components, including battery packs, power electronics, and charging systems, must be meticulously sealed against moisture. However, achieving this is not as simple as applying waterproof coatings or gaskets. The thermal management systems in EVs, which often use liquid cooling, add another layer of complexity. A breach in these systems could lead to coolant mixing with electrical components, creating a hazardous scenario. Engineers must strike a delicate balance between thermal efficiency and waterproofing, ensuring that cooling performance isn’t compromised in the pursuit of water resistance.

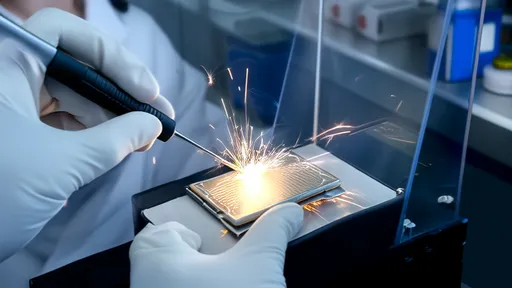

The stakes are particularly high for battery packs, which operate at voltages exceeding 400V in most modern EVs. Even minor water ingress can lead to corrosion over time, degrading performance and potentially causing thermal runaway—a chain reaction of overheating that can result in fires. To mitigate these risks, manufacturers employ multi-layered protection strategies. These include potting critical components in epoxy resins, using hermetically sealed connectors, and designing battery enclosures with robust IP (Ingress Protection) ratings. Yet, as EVs venture into deeper water—whether in off-road scenarios or during flooding events—the effectiveness of these measures is put to the test.

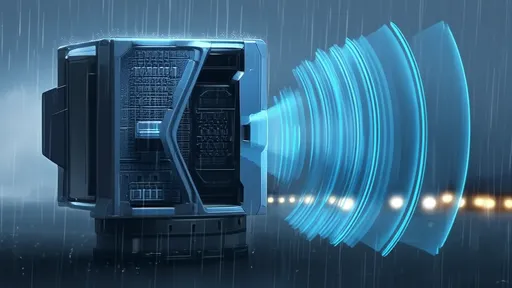

One often-overlooked challenge is the dynamic nature of water exposure. Unlike static waterproofing tests conducted in labs, real-world conditions involve moving water, which can exploit even the smallest vulnerabilities. For instance, high-pressure water jets from driving through heavy rain or submerged roads can force water into seemingly sealed compartments. Automakers are increasingly turning to computational fluid dynamics (CFD) simulations to model these scenarios, identifying weak points before physical prototypes are built. This proactive approach is essential for designing systems that can withstand not just shallow puddles but also sudden immersion in deeper water.

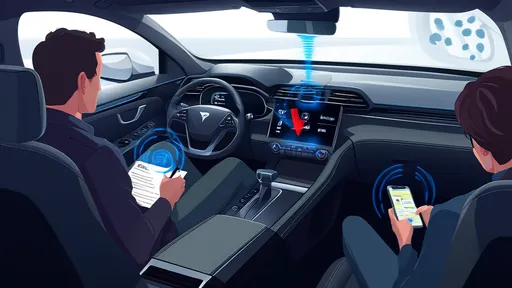

Another critical aspect is the behavior of high-voltage systems during and after water exposure. Even if an EV’s components remain dry, the mere presence of water on external surfaces can alter electrical conductivity, leading to false readings or triggering safety mechanisms. Modern EVs are equipped with sophisticated monitoring systems that can detect insulation faults or leakage currents, often shutting down high-voltage systems preemptively to prevent damage. While this enhances safety, it also means that a relatively minor water encounter could leave a vehicle immobile until systems are thoroughly inspected—a potential inconvenience for drivers.

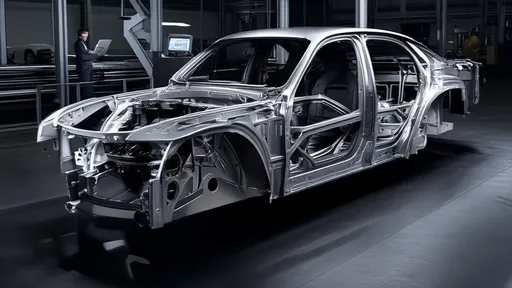

The push for higher wading depths in electric SUVs and trucks adds another dimension to the challenge. Consumers expect these vehicles to perform as well as—if not better than—their gasoline counterparts in off-road conditions. Meeting these expectations requires not only robust sealing but also careful placement of high-voltage components. For example, raising battery packs higher within the chassis can reduce exposure, but this may come at the cost of interior space or vehicle stability. Automakers must navigate these trade-offs while ensuring that their designs remain cost-effective and manufacturable at scale.

Regulatory standards are also evolving to address these concerns. Organizations like the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) are developing more stringent testing protocols for water resistance in high-voltage systems. These tests go beyond basic IP ratings, incorporating real-world scenarios such as prolonged immersion, high-velocity water spray, and temperature cycling. Compliance with these standards is becoming a key differentiator for EV manufacturers, particularly in markets prone to extreme weather or flooding.

Looking ahead, the industry is exploring innovative materials and designs to further enhance water resistance. Self-healing polymers, for instance, could automatically seal minor breaches in enclosures, while hydrophobic coatings might repel water from critical surfaces. Advances in solid-state batteries, which are inherently less susceptible to water damage, could also revolutionize how EVs handle wet conditions. Until then, the focus remains on incremental improvements—better seals, smarter monitoring, and more resilient architectures—to ensure that high-voltage systems can weather the storm, quite literally.

The intersection of water and high-voltage systems in EVs is a testament to the complexities of modern automotive engineering. As the technology matures, the solutions will undoubtedly become more elegant, but for now, the priority is clear: keep the water out, and keep the electrons flowing safely. The journey toward truly waterproof EVs is far from over, but each innovation brings us closer to a future where electric vehicles can conquer any terrain, no matter how deep the water gets.

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025