The global push for sustainable protein sources has led researchers to explore unconventional yet promising avenues. Among these, microalgae-based protein production systems have emerged as a revolutionary approach that simultaneously addresses food security and wastewater treatment. These microscopic photosynthetic organisms are now being harnessed in specialized facilities called microalgae protein factories, where they transform wastewater nutrients into valuable biomass rich in proteins and other nutrients.

Microalgae protein factories represent a paradigm shift in both food production and environmental management. Unlike traditional agriculture that requires arable land and freshwater, these systems thrive on nutrient-rich wastewater from municipal or industrial sources. The algae consume nitrogen, phosphorus, and other compounds considered pollutants in water bodies, effectively cleaning the water while multiplying rapidly. This dual-purpose technology offers a compelling solution to two pressing global challenges: the need for alternative protein sources and the urgent requirement for sustainable wastewater treatment methods.

The process begins with the careful selection of microalgae strains known for their high protein content and robust growth in wastewater conditions. Species like Chlorella, Spirulina, and Scenedesmus have shown particular promise, with protein contents ranging from 50-70% of their dry weight when grown under optimal conditions. These strains are introduced into specially designed photobioreactors or open pond systems that receive pretreated wastewater. The algae then perform their natural photosynthetic magic, converting solar energy, carbon dioxide, and wastewater nutrients into valuable biomass.

What makes these systems truly remarkable is their efficiency. Compared to conventional crops like soybeans, microalgae can produce up to 10 times more protein per unit area. Their growth cycle is measured in days rather than months, allowing for continuous harvests throughout the year. Moreover, the water footprint is significantly lower since the same water can be recirculated within the system after algae removal. This creates a nearly closed-loop system where the primary inputs are sunlight, CO₂, and wastewater that would otherwise require energy-intensive treatment.

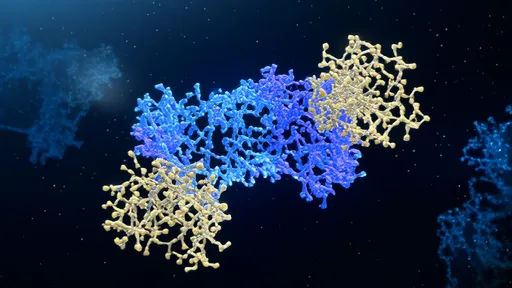

The harvested algae biomass undergoes processing to extract proteins and other valuable components. Depending on the intended application, the protein can be isolated as a concentrated powder or used as part of whole algae flour. The resulting products boast an impressive amino acid profile that often matches or exceeds conventional protein sources. Beyond nutrition, microalgae proteins offer functional benefits in food applications, including emulsification properties and heat stability, making them attractive to food formulators.

Environmental benefits extend far beyond wastewater remediation. Microalgae cultivation actively sequesters carbon dioxide, with estimates suggesting that one hectare of algae ponds can absorb up to 100 tons of CO₂ annually. The oxygen released during photosynthesis improves local air quality, while the reduction in wastewater treatment energy needs translates to lower greenhouse gas emissions. When compared to animal protein production, the carbon footprint is orders of magnitude smaller, positioning microalgae proteins as a truly climate-friendly alternative.

Scaling up this technology presents both opportunities and challenges. Pilot projects in various countries have demonstrated technical feasibility, but questions remain about economic viability at industrial scales. The cost of harvesting and processing algae biomass remains higher than conventional protein sources, though technological advancements are rapidly closing this gap. Another consideration is public acceptance, as algae-based foods represent a departure from traditional dietary patterns. However, with proper education and product development focused on taste and texture, this hurdle appears surmountable.

Innovations in system design are addressing many of these challenges. Automated monitoring systems now optimize growth conditions in real-time, while novel harvesting methods like membrane filtration and flocculation have improved efficiency. Some facilities are experimenting with hybrid systems that combine algae cultivation with other processes, such as biogas production from residual biomass. These integrated approaches promise to enhance both the economics and sustainability of microalgae protein factories.

The potential applications of microalgae proteins are vast and varied. In the food industry, they can serve as ingredients in meat analogs, protein bars, pasta, and dairy alternatives. The aquaculture sector sees promise in algae-based fish feed that could relieve pressure on wild fish stocks currently used for feed production. Even the pharmaceutical industry is exploring microalgae proteins for their bioactive properties and potential health benefits. As technology matures, we may see algae proteins become staples in emergency food supplies and space missions, where resource efficiency is paramount.

Looking ahead, microalgae protein factories could transform urban landscapes. Imagine wastewater treatment plants doubling as protein production facilities, with gleaming photobioreactors lining city peripheries. Such installations would not only provide local food security but also create green jobs and contribute to circular economies. The vision extends to developing regions where conventional agriculture faces limitations - microalgae systems could provide both clean water and nutritious food where they're needed most.

While challenges remain in scaling and optimization, the fundamental promise of microalgae protein factories is undeniable. They represent a convergence of environmental stewardship and food innovation, harnessing natural biological processes to create sustainable solutions. As research continues and more demonstration projects come online, we may be witnessing the early stages of a food production revolution - one where wastewater is no longer seen as a disposal problem, but as the foundation for nourishing future generations.

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025